COMPOSITE “T” BEAM BRIDGE DECK ON TIMBER TOWERS

by Robert E. Eby, P.E.

A unique bridge deck design consisting of reinforced concrete roadway slabs supported by creosoted timber stringers, with a shear connection between the concrete and timber to give composite action of the ”T” beam construction, was developed by the Oregon State Highway Department (1) in 1932. Two viaducts using this new design concept were built on Fourth Street (now Barbur Boulevard) in Portland in 1934. Both viaducts are in service (1988) and carrying more traffic than at the time they were constructed.

The rapid growth of the motor vehicle industry in the 1915 to 1930 period created pressure on highway departments to build new roads and bridges. Obtaining optimum miles of roads from the money available was high priority. Treated timber bridges could be built for about 1/3 the cost of all concrete bridges.

A disadvantage of the wood bridge deck was inability to resist abrasion and wear. C. B. McCullough, Assistant State Highway Engineer for the Oregon State Highway Commission reasoned that a design utilizing the advantage of a reinforced concrete wearing surface to resist compression stresses and a timber support member to resist tension stresses could increase the cost effectiveness of the bridge budget. Extensive tests were made at Oregon State College (2) in 1932 as part of the research program to prove the new concept. Five methods of developing horizontal shear between the concrete flange and the timber stringer stem were investigated. Assumed stress distributions were confirmed by tests and the design criteria established.

Estimates were’ made for the cost of the two structures to compare reinforced concrete construction to the timber-concrete deck construction supported by timber towers. An 80 year service life was assumed for the concrete structures. The estimated cost was $170,000.

With proper design and maintenance, treated all timber structures were expected to have a service life of 30 to 50 years. However, for the economic comparison, the life of the timber-concrete composite design was assumed to be 30 years. The result of the cost comparison resulted in a decided advantage in favor of the timber bridge.

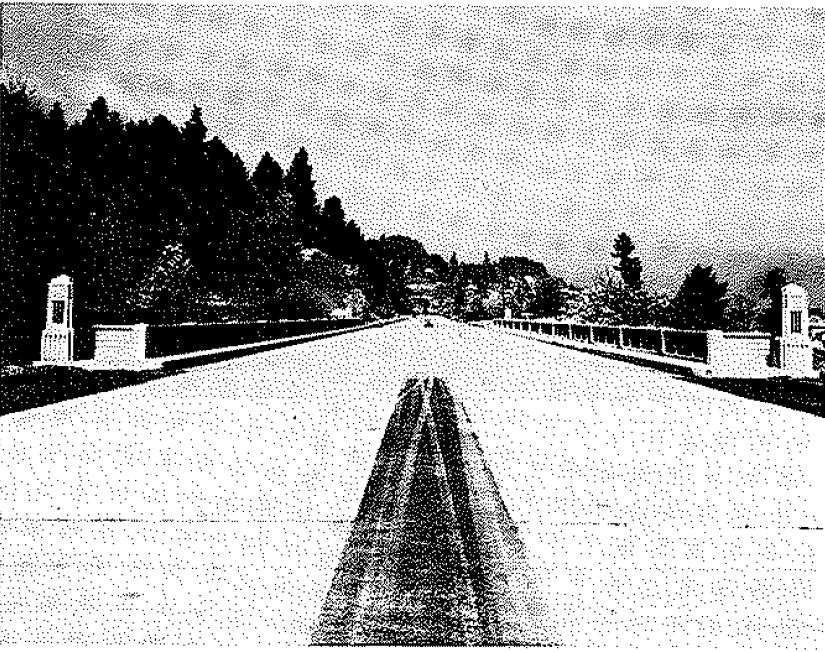

Figure 1. The Newbury Street viaduct.

A contract in the amount of $91,127 for construction of both bridges was awarded in December, 1933. Construction was completed in 1934. The Newbury Street Crossing shown in Fig. 1 is 115 meters (377 feet) long.

Figure 2. Vermont Street viaduct.

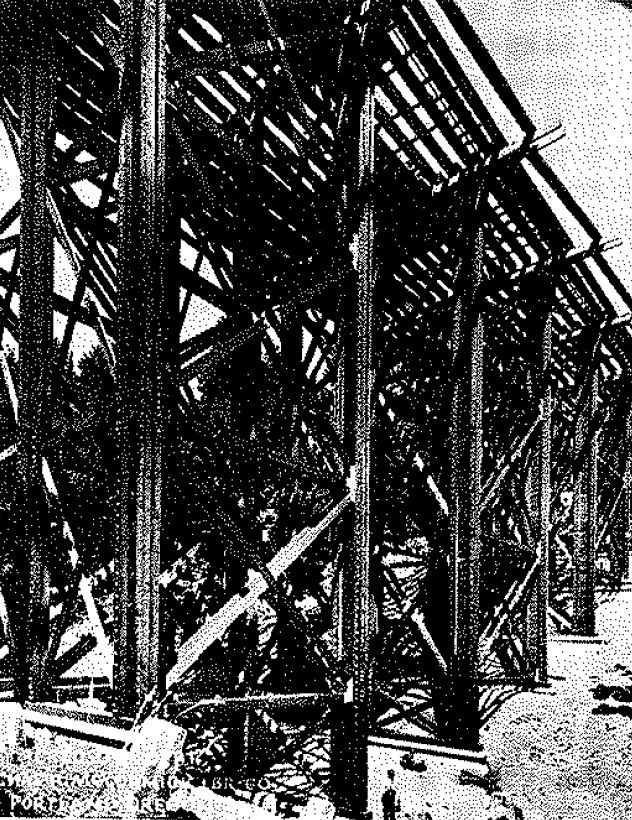

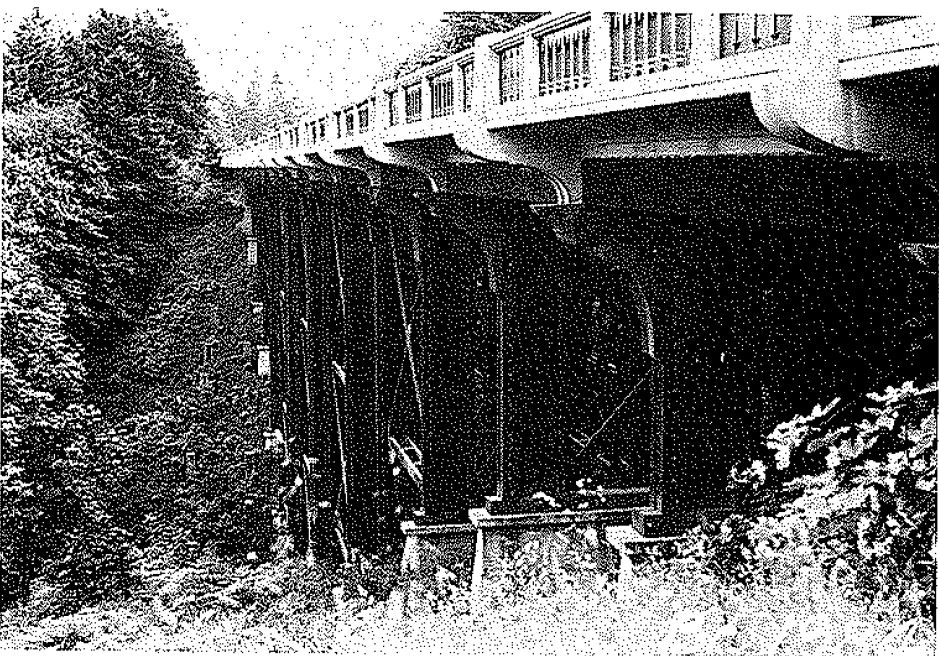

The Timber supporting structures shown in Fig. 3 were also of novel design. A series of towers each included two bents made of three columns and necessary bracing. The columns have an “I” section into which the creosote treated braces and ties are inserted to provide effective symmetrical fastening. Joints are strengthened by use of steel gusset plates. Each column consists of four 203 millimeters x 356 millimeters. (8 inches x 14 inches) creosote treated timbers in the form of an “I” section with a web system of 102 millimeters x 305 millimeters (4 inches x 12 inches) creosoted planking. Two of the 203 x 356’s (8 x x 14’s) are used in each flange of the “I” section. Fig. 4 shows the guard rail construction.

Figure 3. Timber Tower Support Structure

The three columns are made into a bent by a double system of 102 millimeters x 305 millimeters (4 inch x 12 inch) sway bracing. A 508 millimeters by 610 millimeters (20 inch by 24 inch) creosoted timber cap on each bent supports the 203 millimeters x 610 millimeters (8 x 24 inch) creosoted stringers which are the stem of the composite “T” section. Daps in the top of the stringers plus spikes develop the shear resistance between the concrete slab and timber stem.

Figure 4. Guard Rail Construction

All of the timber is Coast Douglas fir which was fabricated prior to treatment in an 55.2 kilopascals (8 pound) empty cell process by the Charles McCormick Treating Company. Any field fabrication required that the contractor, Hoffman Construction of Portland, field treat with hot preservative oil under pressure. All hardware was galvanized.

Maintenance costs for the first 20 years service of the two bridges totaled $2,710 of which only $663 was for the timber portion. Forty-two half caps were replaced between 1964 and 1968 at a total cost of $78,000. Additional maintenance was required in the late 1970s. The cost comparison decision making assumption of 30 years service with minimum maintenance was verified in service.

The two Barbur Boulevard bridges continue to carry a high volume of traffic. Very few people who cross these bridges daily realize that the structures are all timber except for the concrete deck slabs. The sidewalk and rail construction is as esthetically pleasing today as it was in 1934. A total of 198 “McCullough T Beam” timber-concrete composite deck bridges were built in the 1934-1954 era by the state of Oregon. The total lineal length was 7114 meters (23,340 feet). (3)

The long service life of these structures is a memorial to the creativity of Mr. McCullough and the Oregon State Highway Commission in combining timber and concrete in a mode that takes advantage of the inherent strengths of each.

References

- C. B. McCullough, “Highway Viaducts in Oregon of Prefabricated

Timber,” Wood Preserving News, Vol. XII – No. 11, November, 1934. - Oregon State Highway Commission, “Loading Tests on a New Composite-Type Short Span Highway Bridge,” Highway Department Technical Bulletin No. 1, 1932. ‘

- T. K. May, “Composite Timber Concrete Construction,” American Railway Engineers Association Technical Bulletin; Report of Committee 7-Wood Bridges and Trestles, Vol. 56, No. 520. January, 1955

About the author:

Robert E. Eby, P.E.,Retired.

Former Technical Director, Weyerhaeuser Co. Engineered Wood Products

Former Fellow, A.S.C.E.

Comments are closed